Perlite concrete

Main Application

Perlite concrete mixed with cement and water provides a light, insulating concrete suitable for roofs, floors, floor separations, insulating blocks and elements. As Perlite is one of the lightest aggregate materials on the market, it is advantageously used where high insulation capacity is desired.

Limitations

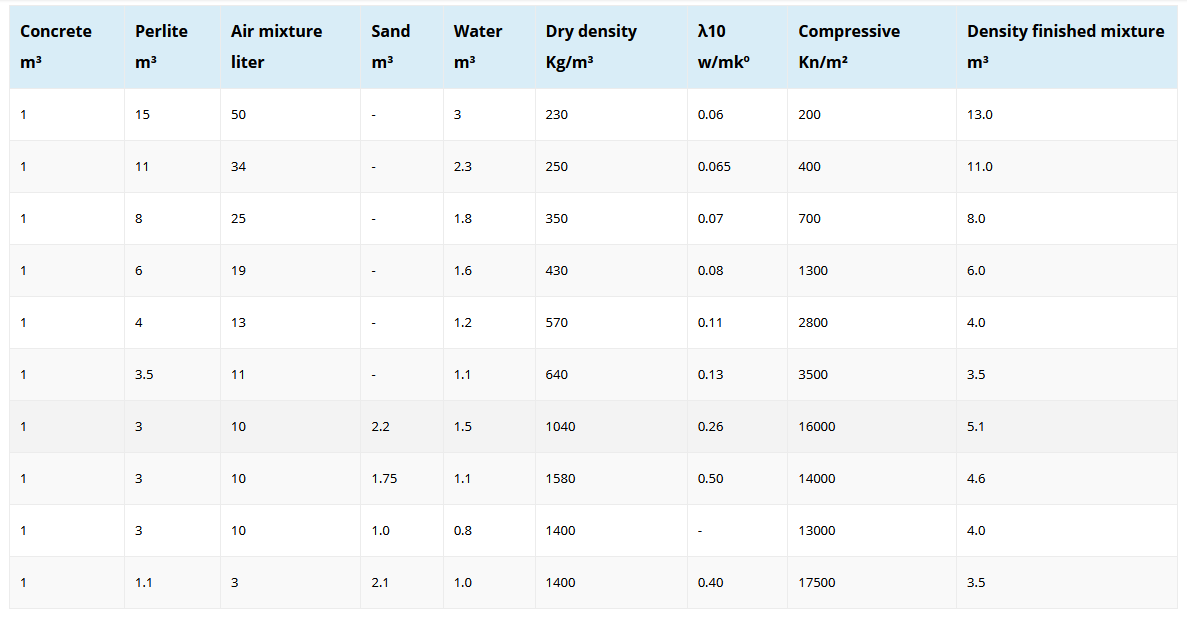

Perlite concrete cannot be used for long bearing elements as the compressive strength is limited (see Table 1). Do not use Perlite concrete between 2 vapor barriers without ventilating it

Technical data:

Perlite concrete provides better insulation performance at any given density than other insulating concrete. Perlite concrete mixtures can be specified within wide limits according to the physical properties desired.

The bulk weight of dry Perlite concrete

You can choose between 230 – 1600 kg / m³. The low densities gives the best insulation values (λ10 from 0.06 – 0.4 W / m ° C). See also Table 1.

Perlite concretes good insulating ability and low density reduces material weight and

installation height compared to other light additions.

At a certain λ value, less material quantity must be transported, both by weight and volume. Perlite concrete can be mixed and transported in the same way as other concrete.

Perlite concretes good insulating ability and low density reduces material weight and

installation height compared to other light additions.

At a certain λ value, less material quantity must be transported, both by weight and volume. Perlite concrete can be mixed and transported in the same way as other concrete.

Applications

Floors:

In unheated Perlite concrete floors such as underlay for carpets and vinyl, a high compressive strength is obtained by mixing sand, cf. Table 1.

If tiles are to be laid, a mixture of 1: 4, t = 50 mm is recommended. If the floor is heated by heating pipes or electric cable, it is recommended to cast perlite concrete in a layer 1: 8, place the heating pipes or cables on this and pour at least 40 mm concrete on top. Perlite is inactive and will not corrode steel pipes.

Floor separations:

In floor separations, the weight is often desired to be reduced. The use of Perlite concrete on load-bearing concrete, steel and the like reduces weight. Compared to normal concrete, 50% weight is often saved.

Perlite concrete as a finishing layer is widely used, due to the low weight and good workability, 40 – 50 mm Perlite concrete gives a good reduction in noise transmission.

Flat roofs:

Perlite concrete is used for heat insulation and fire insulation in flat roof constructions. Often, Perlite concrete is cast on top of profiled steel plates in a thickness of 50 – 100 mm. A fire resistance of 2-3 hours is achieved. A sandwich construction of Perlite concrete and Polystyrene is also used.

Elements and blocks:

Wall elements and building blocks are made of Perlite concrete, avoiding expensive autoclaving. Chimney elements for furnaces are examples where the durability of Perlite concrete is used at high temperatures. Here, Perlite concrete is used alone or with other additives such as pumice.

In unheated Perlite concrete floors such as underlay for carpets and vinyl, a high compressive strength is obtained by mixing sand, cf. Table 1.

If tiles are to be laid, a mixture of 1: 4, t = 50 mm is recommended. If the floor is heated by heating pipes or electric cable, it is recommended to cast perlite concrete in a layer 1: 8, place the heating pipes or cables on this and pour at least 40 mm concrete on top. Perlite is inactive and will not corrode steel pipes.

Floor separations:

In floor separations, the weight is often desired to be reduced. The use of Perlite concrete on load-bearing concrete, steel and the like reduces weight. Compared to normal concrete, 50% weight is often saved.

Perlite concrete as a finishing layer is widely used, due to the low weight and good workability, 40 – 50 mm Perlite concrete gives a good reduction in noise transmission.

Flat roofs:

Perlite concrete is used for heat insulation and fire insulation in flat roof constructions. Often, Perlite concrete is cast on top of profiled steel plates in a thickness of 50 – 100 mm. A fire resistance of 2-3 hours is achieved. A sandwich construction of Perlite concrete and Polystyrene is also used.

Elements and blocks:

Wall elements and building blocks are made of Perlite concrete, avoiding expensive autoclaving. Chimney elements for furnaces are examples where the durability of Perlite concrete is used at high temperatures. Here, Perlite concrete is used alone or with other additives such as pumice.

Others applications

The great sound absorption of the perlite concrete is utilized in deck elements and in T – T beams where a layer of perlite concrete is embedded. Pure Perlite concrete after one of the mixtures in Table 1

Use: Sand should not be mixed, as the room weight must be kept low to achieve maximum sound absorption. In driveways and roads where heating cables have been laid, insulating Perlite concrete is poured under the heating cables to reduce heat loss.

Perlite filling for post-insulation of chimneys and insulating lining

for boilers and ovens are other examples. In addition, Perlite concrete is used as fire insulation for cable and pipe penetrations in walls and floor separations.

Mix

Low speed mixers are recommended (20-100 rpm).

1. Mix all materials except Perlite (cement, water, additives and any other aggregates)

2. Add all Perlite and continue mixing until the material is evenly mixed, 2 – 3 minutes is usually sufficient. Never mix more than 4 min. then Perlite grains are destroyed. Unlike other concrete, a high water content gives better strength in Perlite concrete.

3. Perlite concrete can be drummed, vibrated or pressed.

4. Slow hardening is recommended. The surface must not dry out during the first few days. Vapor curing can be used.

At low water cement figures, Perlite is pre-watered.

1. Mix all materials except Perlite (cement, water, additives and any other aggregates)

2. Add all Perlite and continue mixing until the material is evenly mixed, 2 – 3 minutes is usually sufficient. Never mix more than 4 min. then Perlite grains are destroyed. Unlike other concrete, a high water content gives better strength in Perlite concrete.

3. Perlite concrete can be drummed, vibrated or pressed.

4. Slow hardening is recommended. The surface must not dry out during the first few days. Vapor curing can be used.

At low water cement figures, Perlite is pre-watered.

Casting Perlite concrete is cast like any other concrete. It can be pumped and is easy to repair.