What is Perlite Filter Aid Filtration?

Filtration is the separation of solids from liquids by forcing the liquid to flow through a porous medium and depositing the solids on the medium. A filter aid is a finely divided material which, when added to the liquor to be filtered, helps control flow and solids removal. The septum, usually screen or cloth, serves principally as a support for the cake.

The filter aid forms a porous layer on the septum and thus the filter aid is the filtering medium that traps the solids being removed and prevents them from blinding the septum.

Filter aid filtration is mechanical, not chemical in nature. Irregularly shaped particles interlace and overlay in a fashion that leaves up to 90% voids or open spaces. These voids form billions of microscopically fine interstices between the filter aid particles. The size of these openings is so minute that the unwanted solids are strained from the liquid. The vast number of openings compensates for their small size resulting in fast flow rates and brilliant clarity.

Good filter aids are light in weight, chemically inert and form high porosity filter cakes to maintain free flow of the liquid. The structure of the particles must be such that they will not pack too closely. This not only permits high initial liquid flow but also provides pore spaces to trap and contain the filterable solids and leave a high percentage of channels remaining open for flow.

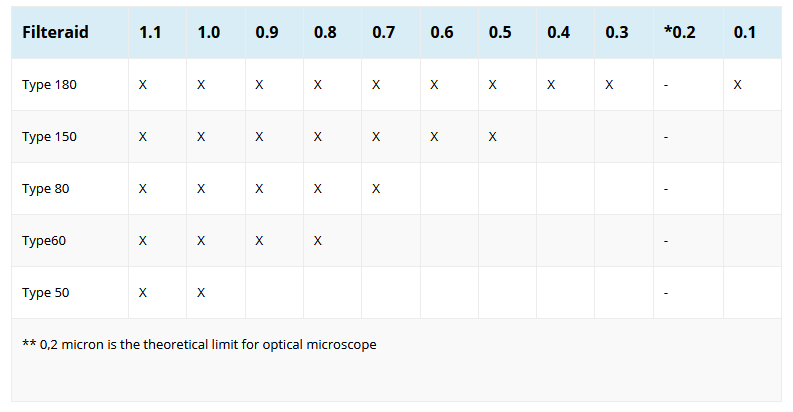

Particle size distribution must be tailored to permit precoating on coarse wire and yet give the desired flow rate and clarity. Nordisk Perlites filter aids meet these criteria. They are available in variety of grades to suit the solids removal requirement of any application.

The filter aid forms a porous layer on the septum and thus the filter aid is the filtering medium that traps the solids being removed and prevents them from blinding the septum.

Filter aid filtration is mechanical, not chemical in nature. Irregularly shaped particles interlace and overlay in a fashion that leaves up to 90% voids or open spaces. These voids form billions of microscopically fine interstices between the filter aid particles. The size of these openings is so minute that the unwanted solids are strained from the liquid. The vast number of openings compensates for their small size resulting in fast flow rates and brilliant clarity.

Good filter aids are light in weight, chemically inert and form high porosity filter cakes to maintain free flow of the liquid. The structure of the particles must be such that they will not pack too closely. This not only permits high initial liquid flow but also provides pore spaces to trap and contain the filterable solids and leave a high percentage of channels remaining open for flow.

Particle size distribution must be tailored to permit precoating on coarse wire and yet give the desired flow rate and clarity. Nordisk Perlites filter aids meet these criteria. They are available in variety of grades to suit the solids removal requirement of any application.

- Perlite Filteraid Health Certificate 12 January 2021

- Perlite is not contaminated with asbestose 12 January 2021

- Perlite and Dioxin 12 January 2021

- General information 12 January 2021

- Perlite - Technical data 12 January 2021

- Perlite and Comparison of Diatomaceous earth / Kieselguhr 12 January 2021

- Overview of Perlite Filter Aid Types 12 January 2021

- Perlite Filter Aid for Breweries 11 January 2021

- Perlite Filter Aid for Wine Production 11 January 2021

- Perlite Filter Aid - Its Use in Swimming Pool Filters 11 January 2021