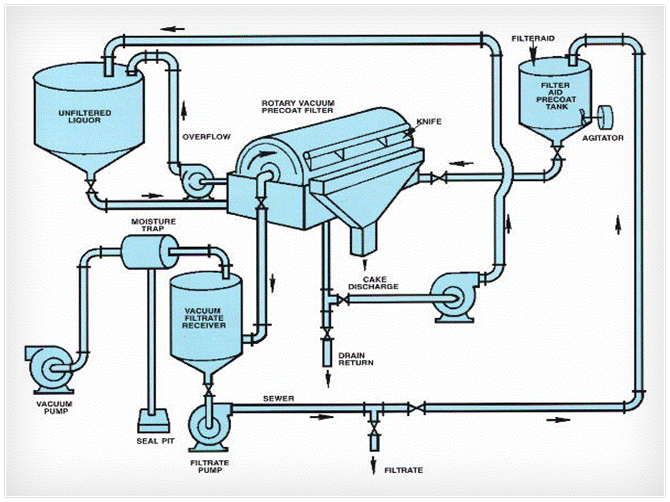

Rotary precoat filters

Relatively thick precoats, 50-150 mm, are used on rotary drum filters.

The precoat is formed on a drum covered with cloth or metal septum by pumping a slurry of clean liquid with 2 to 5% filter aid to the filter and returning the liquid precoat tank. The septum should be kept clean, as a dirty septum can be source of trouble in causing cake cracking, no uniform precoat thickness, cake falling off and low flow rates. Depending upon the filter aids permeability, the vacuum capacity of the filter and the filter drum rotation rate, a 50-100 mm precoat can be applied in ½ to 2 hours. Too rapid precoating rate and too high filter aid concentration in the slurry can cause excessive cake shrinkage and cracking although small hairline cracks are normal.

During the operating cycle, passage of the process liquid through the precoat leaves the filterable solids in a relatively thin film which just penetrates the precoat surface.

A mechanically operated knife blade continuously shaves off the filterable solids and leaves a clean fresh filtering surface. The knife is usually set to cut between 25 and 250 microns deep. Selection of the proper depth of cut depends mostly on the nature and quantity of the filterable solids, and the degree of penetration into the cake.

The most economical drum speed is determined largely from the characteristics of the filterable solids. As a general rule, the slowest drum speed compatible with productions requirements is recommended. Speeds commonly range from 1 to 1/5th revolution per minute.

For any given operation the flow rate in l/m²/hour depends on the knife cut, drum speed, grade and type of filter aid used, the filtration resistance of the suspended solids, and the viscosity of the process liquid. Flow rate is dictated by production requirements, thus the drum speed and the cake knife cut must be regulated to give needed throughput. This may result in higher filter aid consumption, but may be justified by peak demands, lack of sufficient filter capacity, or a temporary run of hard-filtering liquor. Another way to increase flow rate (again at the expense of filter aid economy) is to add filter aid to the charge liquor. On a long term basis the purchase of additional filter equipment proves most economical.

Selection of the best grade and type of filter aid is based upon determining the one which will minimize penetration of the suspended solids into the precoat cake so as to make possible the thinnest cuts to maintain desired flow.

Three outstanding advantages of Perlite filter aids are:

economy because of high volume-to-weight ratio

high efficiency in filtering high solids contents liquids

excellent resistance of the filter aid cake to cracking.