Portland cement plasters made with Perlite aggregate instead of sand offer many advantages. They are more fire resistant, better insulators, and weigh approximately 60% less than conventional cement and sand plasters. With the addition of fiber reinforcement, superior crack resistance is achieved. In addition, fiber reinforced Perlite cement plaster panels can be safely and easily handled in the field.

Fiber Reinforced Perlite Cement Plasters

The addition of alkali resistant glass, polypropylene or acrylic fibers makes possible the manufacture of prefabricated steel stud, lath, and plaster exterior wall panels for high rise structures. Perlite cement plasters with fiberglass reinforcement can also be used for fire protecting structural steel columns or for any normal application where conventional cement plasters might be used.

Panelizing

Fiber reinforced Perlite cement plaster panels using steel studs may be constructed in a fabricating shop and shipped to the job site for installation. On smaller projects, it has proven more efficient to prefabricate the wall panels on each floor of the building and tip them into place.

Mixing

In batch mixing, all required water is placed in the mixer and cement is added and mixed for approximately 1 minute until the slurry is uniform. Perlite aggregate and chopped fiber is added as the mixer is rotated. Mixing should continue until the mix is thoroughly blended but should not exceed 4 minutes. The batch should not be over mixed.

Mix Design Data

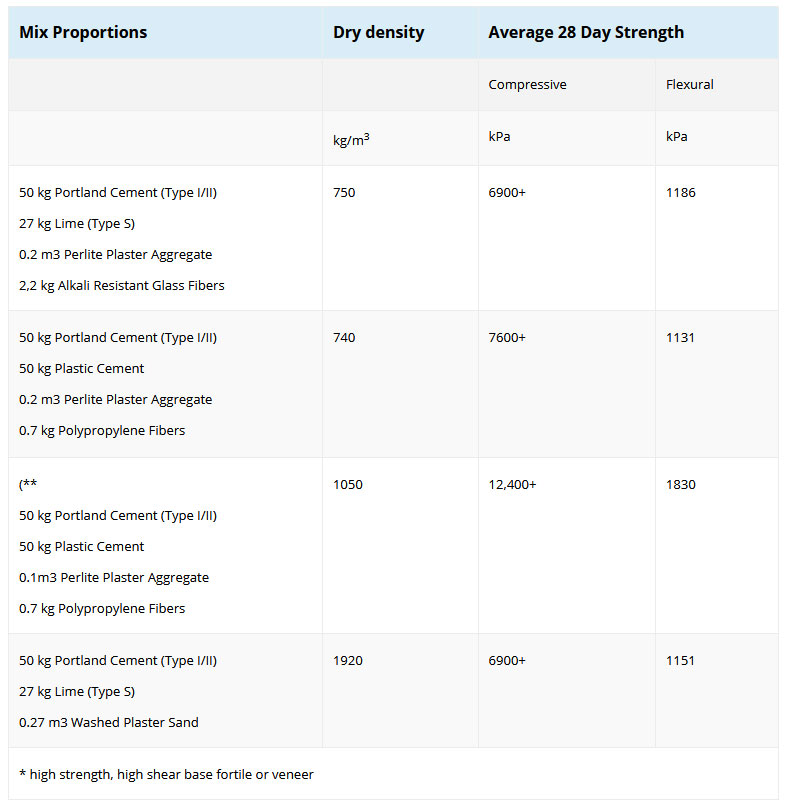

The proper proportions of materials for various fiber reinforced Perlite plasters are shown following table.

Fiber Reinforced Perlite Plaster Mix Proportions and Properties

Application

Fiber reinforced Perlite cement plaster may be machine or hand applied. For machine application, 13mm long fibers are preferred as they do not tend to ball up in the equipment. On vertical applications, plastering should consist of separate scratch and brown coats. The brown coat may be applied as soon as the scratch coat has set sufficiently hard to support subsequent coats. For horizontal applications (panel construction), plaster may be poured in one coat and screeded level. When plaster begins to set it should be floated to provide compaction. Brown coats should be flat and even but be sufficiently rough to receive finishes.

Finishing

To assure proper hydration of the cement, the basecoat plaster should be kept damp for at least 48 hours. After the basecoat has been allowed to dry at least 5 days, finish materials may be applied following manufacturer’s recommendations. Fiber reinforced Perlite cement plaster basecoats accept a wide variety of finishes such as cementitious color and texture coats, stucco, polymerized cementitious coatings, tile, or masonry veneer. Tests have shown that the basecoat exceeds required shear values for tile and veneer by 300-400%. Expanded Perlite aggregates can be manufactured to weigh from 40 kg/m3 to 240 kg/m3 making it especially suitable for a number of applications in the construction industry. In addition to cement plasters, Perlite aggregate may be used in a variety of insulating plasters, lightweight insulating concretes, masonry wall insulation, cryogenic insulation, floating floor applications, and in the manufacture of simulated stone and brick.

Proportions and application

Mix Perlite Portland cement in a paddle type plaster mixer. Mix required amount of water and air entraining agent in the mixer followed by the cement and mix until a slurry is formed. Add proper amount of Perlite aggregate to the slurry and mix until required wet density is reached. See Table 1 for proper mix proportions of all Perlite Portland cement based plasters and apply in three coats to not less than the specified minimum thickness. Note: On small jobs, two coat application, is acceptable. Apply second coat as soon as the first coat has attained sufficient rigidity. Sand may be mixed with Perlite aggregate in the maximum ratio of 1:1 to increase the tensile strength except in fire rated construction.